Nyob rau hnub tsis ntev los no, qee tus neeg siv khoom tsis meej pem yuav ua li cas los tsim lub brewery, thiab dab tsi yog lub tsev brewery txheej txheem thiab txheej txheem, tam sim no cia peb qhia koj yuav ua li cas tsim nws.

Part 1: Peb yuav ua li cas rau lub tsev brewery?

Kev Ua Haujlwm Kev Ua Haujlwm

Paub meej tias qhov kev thov brewing

Ua ntej, peb yuav paub meej ntxiv txog koj cov brewery, xws li npias hom, brewery batchese ib hnub twg los yog sij hawm, npias plato, lub sij hawm fermentation, brewery qhov siab, thiab lwm yam.

Tom ntej no Peb yuav qhia koj raws li koj qhov kev pom zoo thiab cov ntsiab lus.Peb yuav kos npe rau daim ntawv cog lus tom qab ob qho tib si pom zoo cov nqe lus ntawm kev sib koom tes thiab rov lees paub qhov kev pom zoo, nqe, kev teeb tsa, txheej txheem brewing ua ntej cov nqe lus.

1.3 Kev npaj ua haujlwm ua ntej ntau lawm

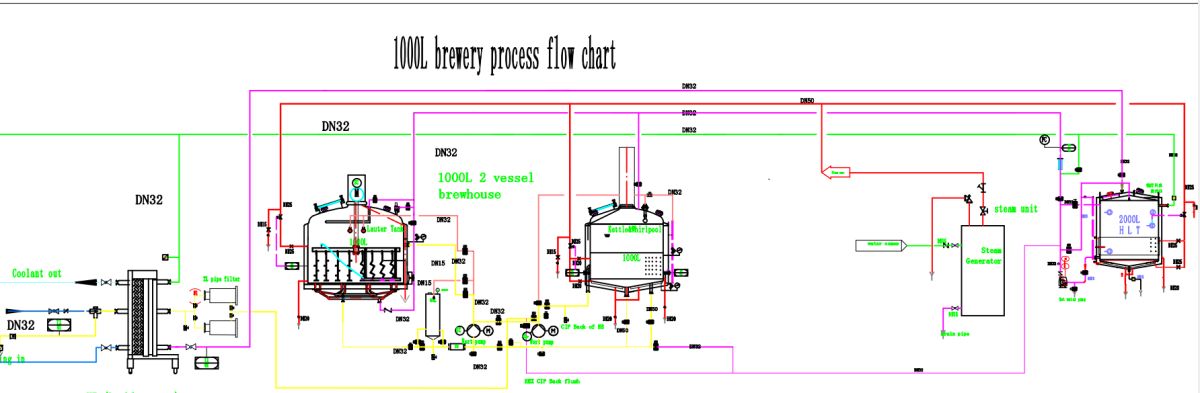

Rov xyuas tag nrho cov lus pom zoo, kev teeb tsa, flowchart thiab rov lees paub cov ntsiab lus ntawm cov khoom siv brewery.

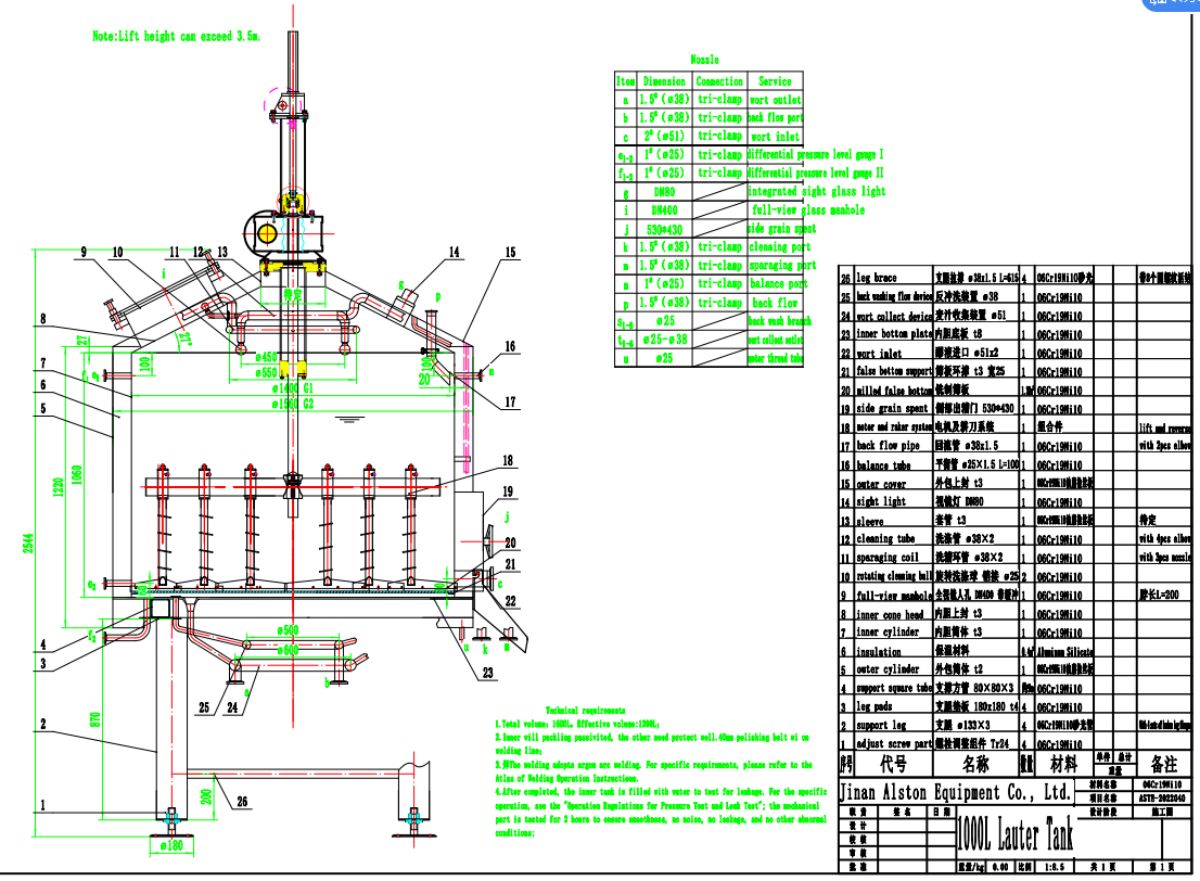

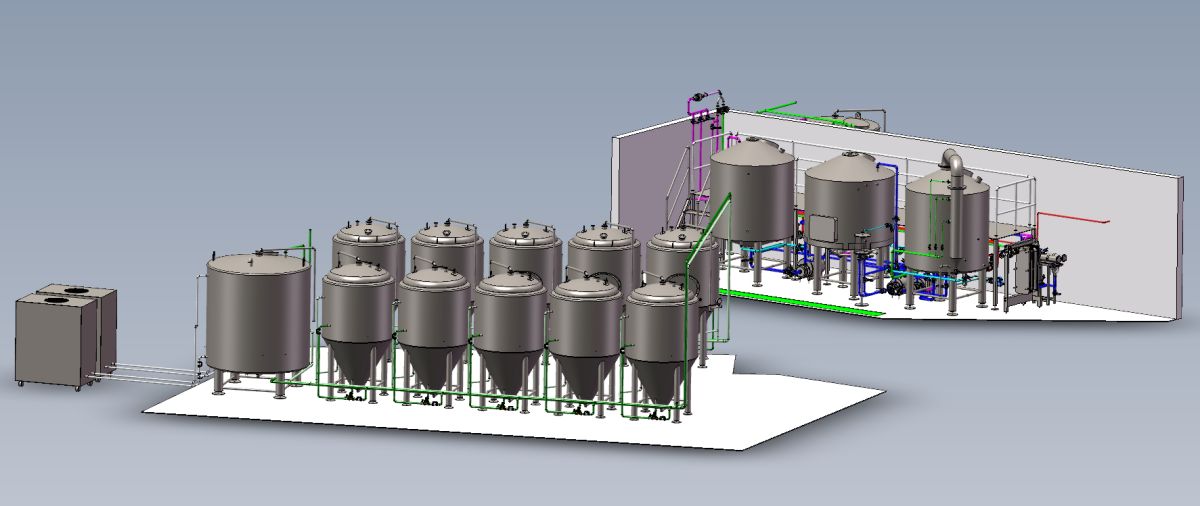

Thiab lub tank kos duab thiab 3D brewery qauv yuav ua thiab qhia rau koj paub meej, koj yuav pom tias koj brewing zoo li cas.

1.4 Ramaterial npaj

Ramaterial booking: peb yuav book cov ntaub ntawv raw thiab lub taub hau tais ua ntej raws li paub tseeb tias tank daim duab, thiab lwm yam accessories yuav booking, xws li lub cev muaj zog, twj tso kua mis, chillers, raws li cov khoom no xav tau UL Certificate, uas yuav siv sij hawm ntev dua.

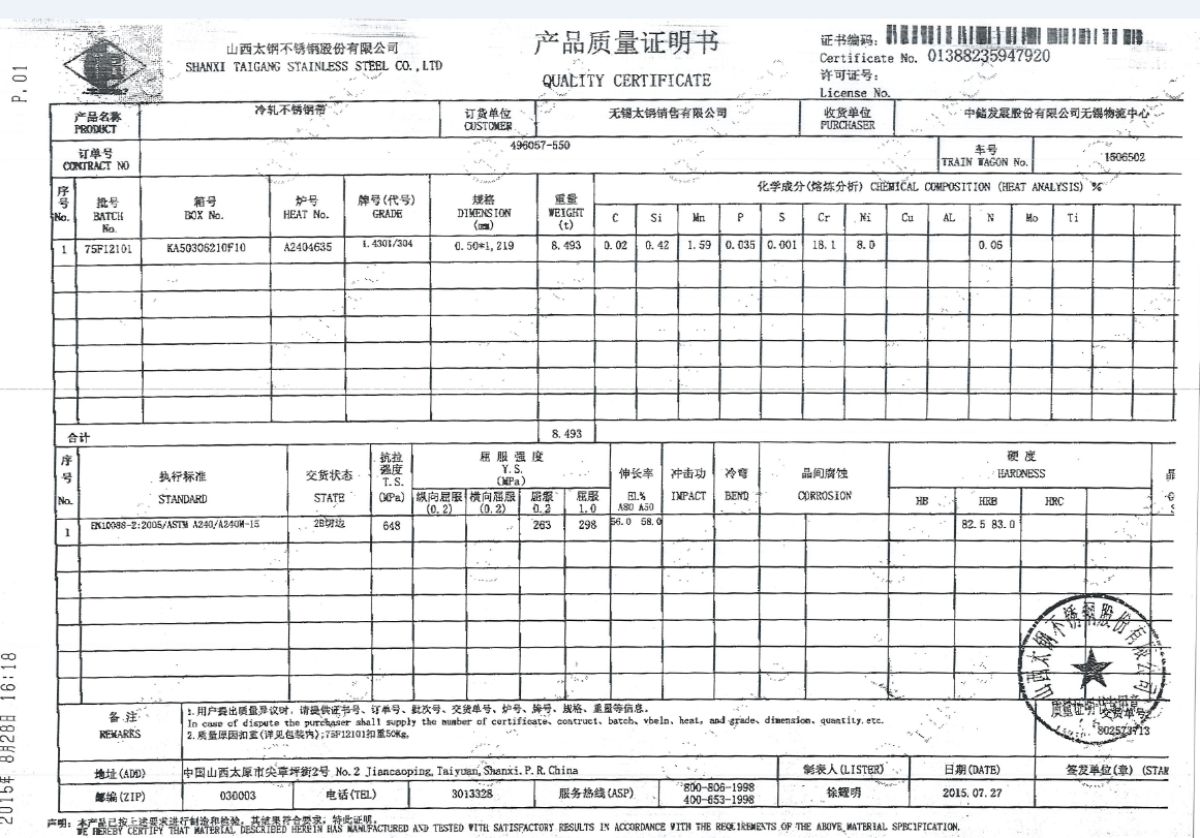

Thaum cov khoom tau mus txog peb lub Hoobkas thiab npaj rau kev tsim khoom, peb yuav xa peb cov ntaub ntawv rau koj, thiab koj yuav pom cov khoom siv, thickness, qauv thiab lwm yam.

(SS daim ntawv pov thawj zoo rau kev siv.)

1.5 Pib rau kev tsim khoom

-Material txiav: Laser txiav, raug txiav, tiaj ntug tsis muaj burrs.

-Sheet hlau: Kev kho cov phaj thiab lwm yam txheej txheem raws li kev tsim khoom.

-Assembly: Vuam lub khob hliav qab thiab lub tog raj kheej ua ke, dimple txias tsho, ob txhais ceg thiab lwm yam.

Vuam txais TIG welding txoj kev, uas muaj cua nruj zoo dua thiab tuaj yeem txo qhov porosity ntawm vuam thaum vuam ntawm lub nkoj siab.

-Polishing: Sab hauv nto yuav kho nrog tshuab polishing, thiab vuam kab polished rau ib txoj siv kom pom zoo.Tom qab ntawd, lub tank sab hauv yuav kho nrog packling pasivition, Internal nto roughness yog 0.4um.

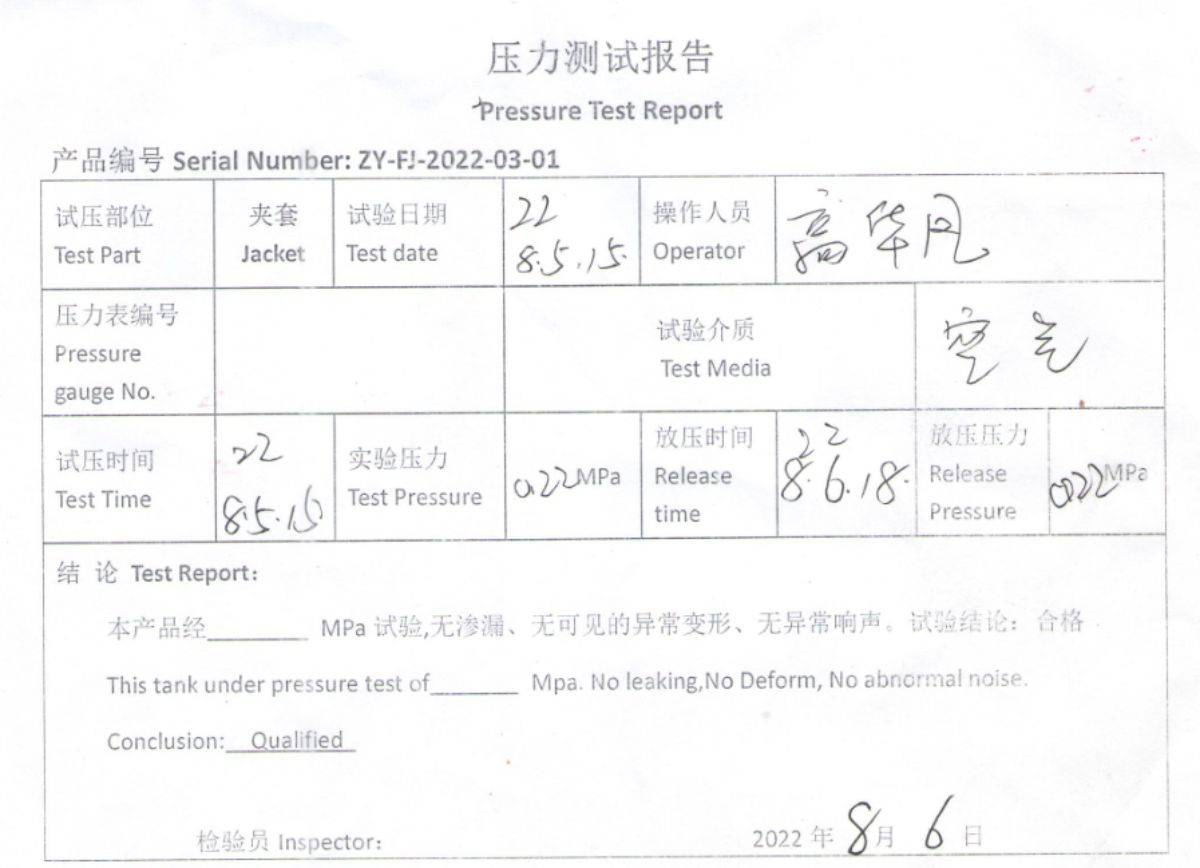

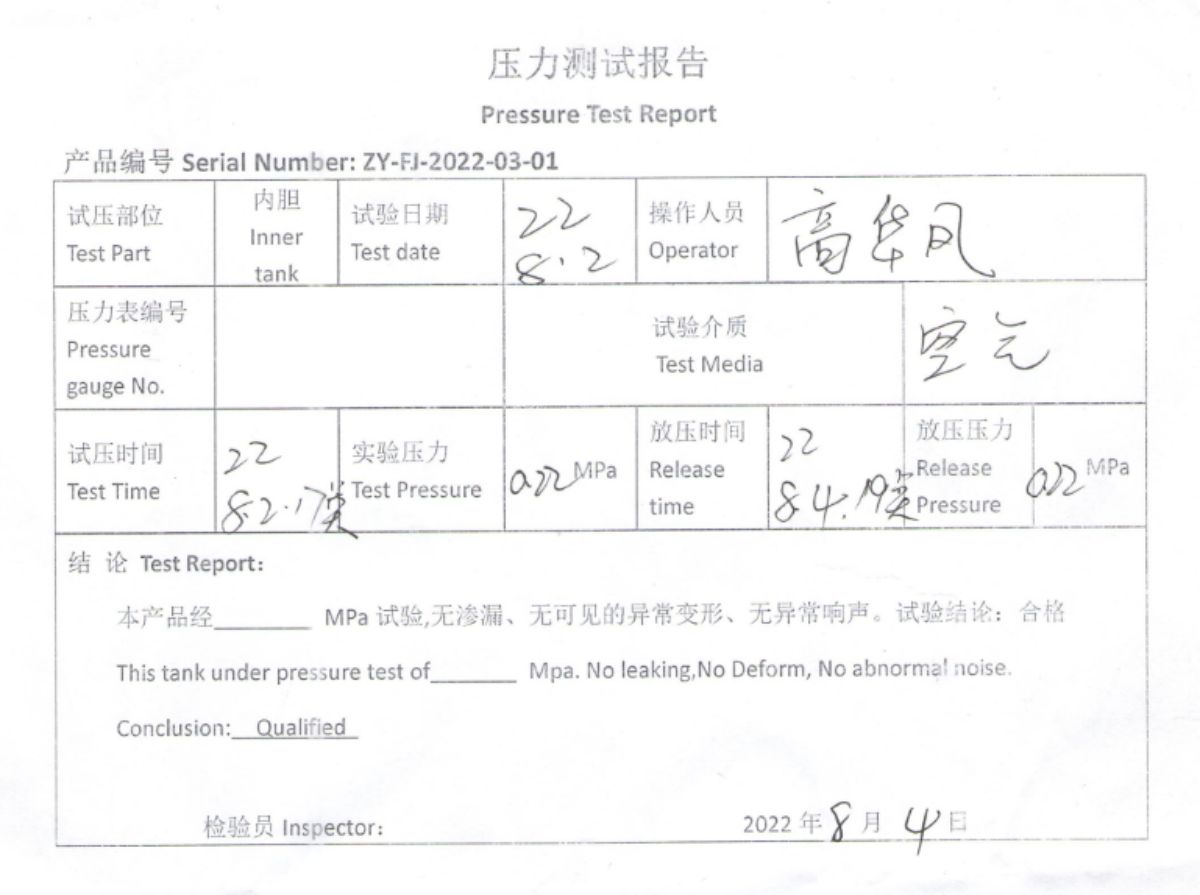

- Kev sim siab: Tom qab ua tiav, lub tog raj kheej thiab lub tsho yog hydraulically kuaj.Kev ntsuas siab ntawm lub tank sab hauv yog 0.2-0.25mpa, thiab qhov ntsuas siab ntawm lub tsho dimple yog 0.2MPa.

-Kev tshuaj xyuas ntau lawm: Nws yuav raug kuaj xyuas tom qab ua tiav txhua txoj haujlwm, thiab muaj Daim Ntawv Cuam Tshuam rau cov txheej txheem tom ntej.Tom qab ua tiav cov tso tsheb hlau luam, peb tus neeg kuaj xyuas yuav xyuas cov ntsiab lus thaum kawg thiab qhia rau peb lub rooj sib dhos ua ke kom txav mus rau kauj ruam tom ntej.

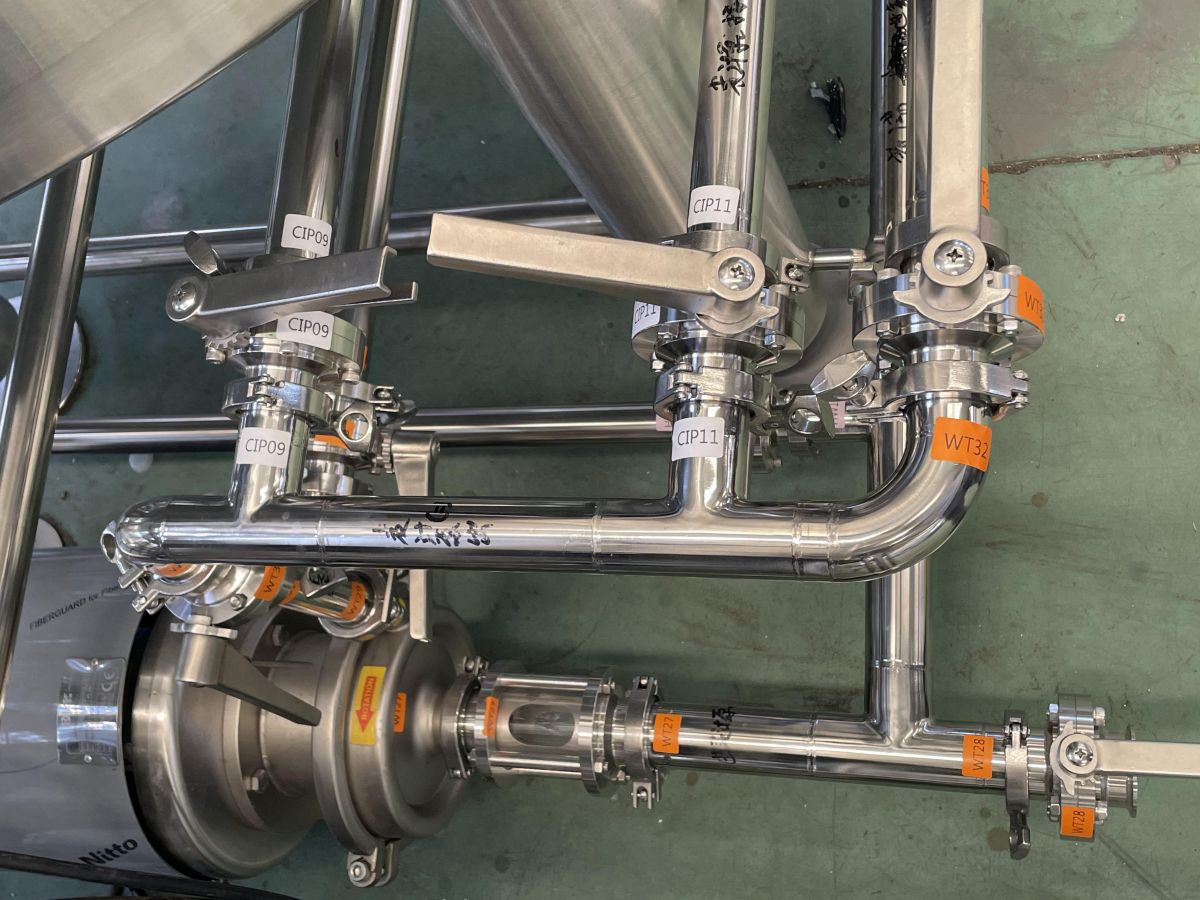

-Pipeline Assembly: Brewhouse pipelines yuav txuas raws li brewing flowchart thiab peb yuav xav txog lub raj xa dej yog qhov yooj yim thaum brewing, thiab glycol pipeline pre-assembled raws li layout.

-Debugging: peb yuav txuas cov dej thiab hluav taws xob los ua cov brewery khiav hauv peb lub hoobkas.

Ntawm no nws yog debugging video peb tau ua ua ntej sim peb lub cev.Pls xyuas nws:https://www.youtube.com/watch?v=wCud-bPueu0

-Package: Tom qab ua tiav qhov kev debugging, peb yuav lo cov ntawv lo ntawm txhua qhov kev sib txuas thiab cov kav dej kom yooj yim installation hauv qhov chaw.Thiab yuav pacakged nws nrog Bubble zaj duab xis thiab anti-kev sib tsoo daim ntaub, thiab lwm yam.

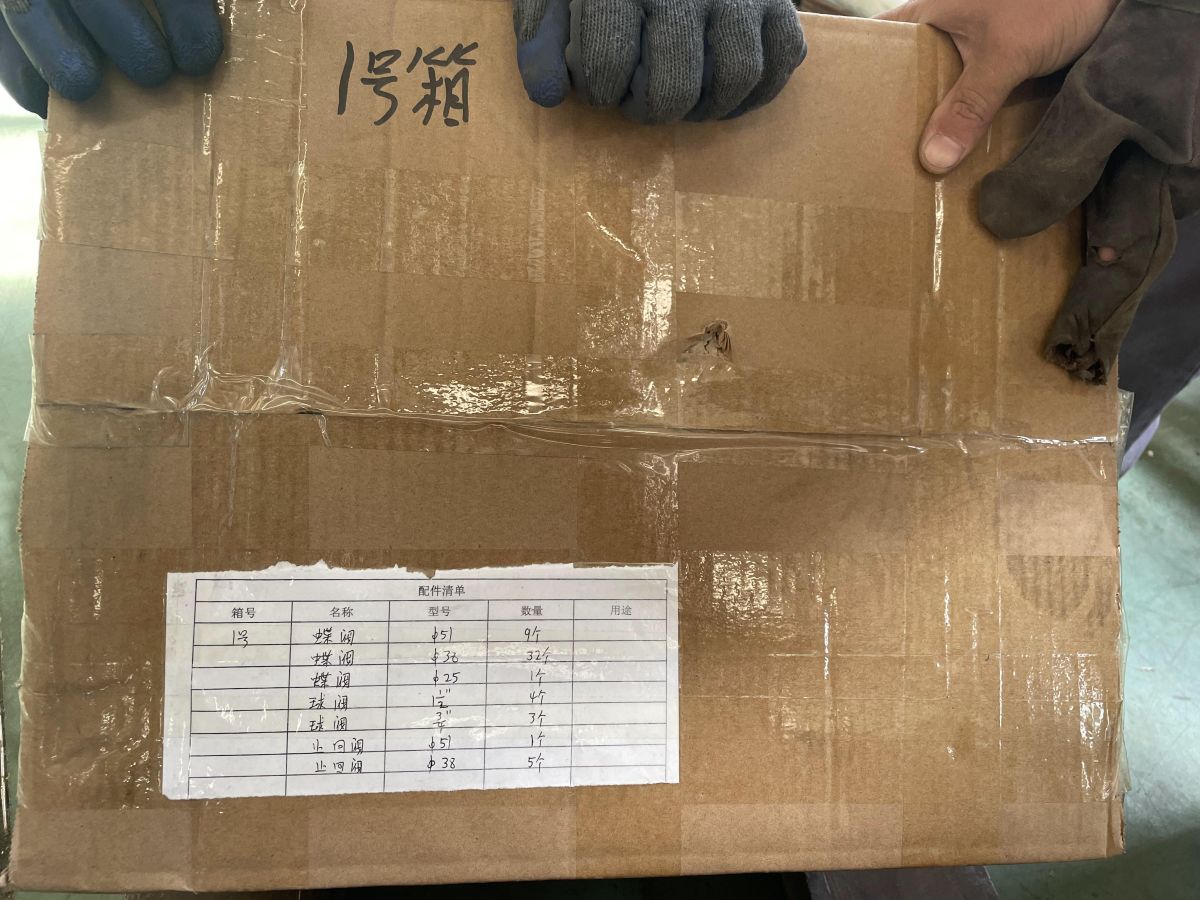

Tag nrho cov li qub thiab fittings yuav muab qhwv nrog yas qhwv thiab lub tank yuav ntim los yogtxhawb raws li cov khoom siv dimension thiab ntim loj.

-Kev thauj khoom thiab xa khoom: Cov cuab yeej yuav thauj khoom tom qab peb tau lees paub hnub xa khoom thiab thauj khoom.Tag nrho cov pob yuav muab cov ncauj lus kom ntxaws cim dab tsi yog cov khoom siv sab hauv thiab xa peb cov neeg siv khoom tom qab xa khoom.

Part 2: Peb yuav ua li cas rau kev tsim brewery?

2.1 Brewhouse: Zoo sib xws nrog koj qhov kev thov brewing.

Brewhouse ib feem yog qhov tseem ceeb tshaj plaws nyob rau hauv tag nrho brewery, uas ncaj qha cuam tshuam nrog wort thiab npias zoo.Brewhouse tsim yuav tsum ua raws nraim li koj daim ntawv qhia brewing, piv txwv li qhov nruab nrab npias npias / plato.Xyuas kom tseeb tias cov txheej txheem Mash lossis lautering tuaj yeem ua tiav hauv lub sijhawm tsim nyog.

Lauter tank: Piv txwv li 1000L brewery, txoj kab uas hla ntawm lauter tank yog 1400mm, thaum lub wort yog 13.5 degrees, malt pub tus nqi yog 220KG, cov khoom siv efficiency yog rau 75%, thiab lub thickness ntawm lub grain txheej yog 290 hli;Thaum lub wort yog 16 plato, tus nqi pub mis yog 260KG, lub tank ntim siv rau 80%, thiab grain txaj thickness yog 340mm.Qhov ntawd yog los xyuas kom meej lub thickness ntawm cov lim txheej ua tau raws li qhov yuav tsum tau ua brewing, tsis cuam tshuam rau kev pom ceev thiab ua kom cov khoom ua tau zoo.Thaum kawg los txhim kho cov zis ib lub sij hawm los ntawm kev txo lub sij hawm pom.

Boiling kettle: Lub thawv ntim ntim tsim raws li 1360L wort ua rau boiling, thiab siv ntim yog 65%.Vim hais tias ntawm wort concetration yog txheeb ze dua nyob rau hauv America, daim ntawv yuav ntau ntau thaum boiling.Txhawm rau tiv thaiv kom tsis txhob muaj npuas dej ntws los ntawm lub lauj kaub thaum lub sijhawm boiling, peb siv qhov yuam kev ncig ua haujlwm los txhim kho tus nqi evaporation kom ntseeg tau tias qhov evaporation yog 8-10% thiab txhim kho qhov kub kub.Kev quab yuam ncig nrog lub raj xa dej pab ua kom cov evaporation nce, thiab DMS qhov xwm txheej thiab cov ntsiab lus tsis pub dhau 30PPM, nws yuav txo cov cua sov thauj khoom thiab ua kom muaj kev ruaj ntseg ntawm wort chroma thiab tsis txhob wort Maillard cov tshuaj tiv thaiv.

2.2 Tsawg zog noj hauv brewery

Condensor system: Lub boiling boiling boiling boiling dej txais yuav steam condensation rov qab system, nws yuav pab txhim kho cov dej rov qab thiab txuag dej thiab hluav taws xob noj nyob rau hauv tag nrho cov brewery.Cov dej kub rov qab nyob ib ncig ntawm 85 ℃, thiab cov dej kub rov qab muaj peev xwm ntawm 150L rau txhua pawg;Qhov ntawd txhais tau tias nws yuav txuag tau qhov hluav taws xob 18kw ib pawg ntawm cov dej kub ntawm 25-85 ℃.

Wort cooler: Lub wort tshav kub exchanger cheeb tsam xam los ntawm cov txheej txheem brewing thiab ua kom tiav cov txheej txheem txias nyob rau hauv 30-40 feeb, thiab dej kub kub ntawm 85 ℃ tom qab heax txauv, tshav kub exchanger efficiency ntawm ntau tshaj 95%.Yog li ntawd, peb yuav xyuas kom meej qhov siab tshaj plaws lub zog rov qab thiab txo cov nqi tsim khoom.

2.3 Ib qho yooj yim brewing thiab txo kev tswj hauv cov txheej txheem brewing

Ib tug ob chav strainer configured, nyob rau hauv cov ntaub ntawv tus neeg siv brewing dhau hoppy npias.Yog li peb coj zoo lav ntawm phaj kub exchanger, uas yog qhov nyuaj tshaj plaws rau kev tu.

Lub twj tso kua mis dual yog tsim nyog rau chav tsev glycol, rau kev lav zoo thaum muaj kev tswj xyuas kev thov, txhua lub twj tso kua mis tuaj yeem hloov tau yooj yim rau kev khaws cov khoom tsis tu ncua.

Dual chiller configured, nrog tib lub hom phiaj zoo li glycol twj tso kua mis.

Glycol twj tso kua mis siv lub twj tso kua mis siab tas li thiab ua kom lub siab tib yam hauv cov kav dej glycol tag nrho, tiv thaiv lub valve soleniod thiab nthuav dav siv lub neej.

Tag nrho cov ntsiab lus no yog rau kev ua haujlwm ruaj khov nyob rau hauv tag nrho brewery ruuning, thiab coj koj ib tug zoo kev nyob rau hauv lub brewing txheej txheem.

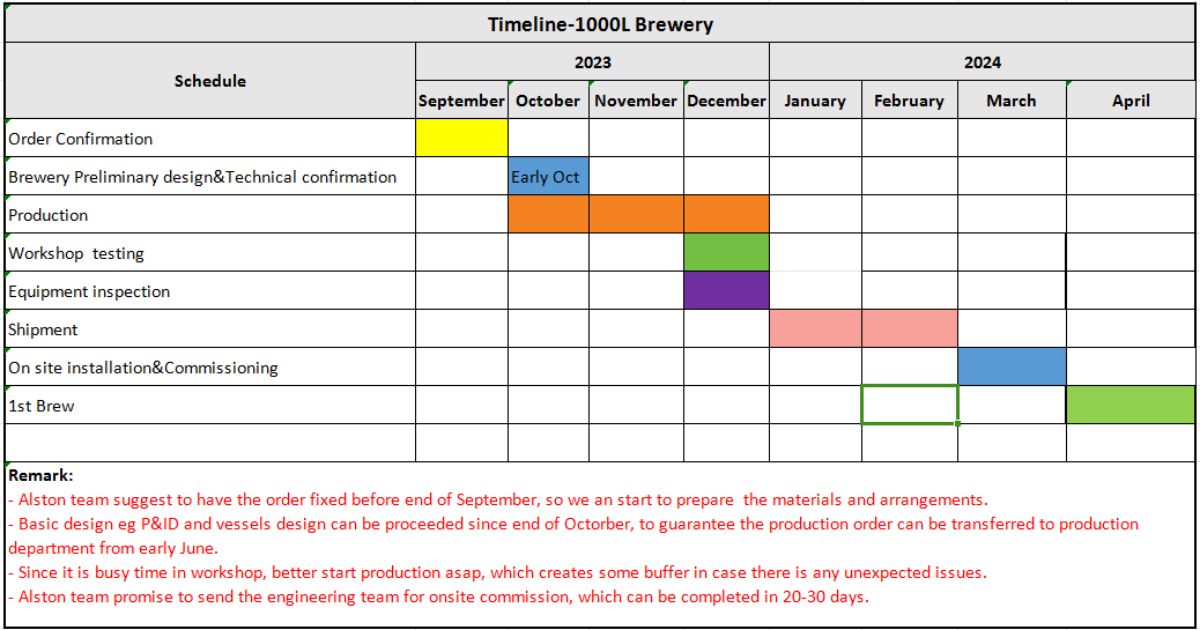

Ntu 3: Lub sijhawm npaj yuav tsum tau ua li cas?

Tam sim no txhawm rau txhawm rau tshem tawm cov txheej txheem kev txiav txim, peb tau ua lub sijhawm teem sijhawm ntawm brewery system, pls pom qhov ntawd.

Vam tias peb tuaj yeem pab koj los tsim kom muaj lub chaw ua haujlwm zoo tshaj plaws hauv koj txoj kev npaj.

Thaum kawg, peb tab tom nrhiav kev ua haujlwm nrog koj sai sai.Los ntawm kev koom tes no, koj yuav xav tias peb cov kev pabcuam thiab muaj txiaj ntsig.Tsis tsuas yog peb yuav tsum tsim kom muaj lub brewery zoo meej rau koj, peb kuj tseem tsom ntsoov rau kev tsim kom muaj kev sib koom tes ntev ntev kom ua tiav qhov kev yeej-yeej ntawm peb ob sab.

Ua tsaug rau koj lub sijhawm.

Ua tsaug!

Post lub sij hawm: Sep-18-2023