Cia peb pom cov ntsiab lus ntawm cov khoom siv brewery, qhov no yog 20HL qhov no yog 3 lub nkoj nrog mash kettle, lauter tank, kettle whirlpool thiab ntxiv dej kub tank ua ke.

Los ntawm qhov teeb tsa brewery no, Ua ntej lub Brewhouse Highly matched nrog koj brewing thov.

Tus tsim keeb kwm yav dhau yog raws li plato 12-16 kom tau raws li cov txheej txheem brewing sib txawv thiab npias.Lub ntim ua haujlwm yog 20HL rau txhua lub nkoj, tab sis rau tag nrho cov ntim yog li 3200L, rau lauter tank, txoj kab uas hla yog 2000mm, Thaum lub wort yog 16 plato, tus nqi pub mis yog 500KG, lub tank ntim siv rau 80%, thiab grain txaj. thickness yog 340mm, thiab tsis ntau tshaj 350mm, uas yuav cuam tshuam qhov pom ceev thiab brewing efficiency.

Boiling kettle: Lub ntim ntim tsim raws li 2320L wort ua ntej boiling, thiab siv ntim yog 65%.Vim hais tias ntawm wort concentration yog txheeb ze dua nyob rau hauv North America, daim ntawv yuav ntau ntau thaum boiling.Txhawm rau tiv thaiv kom tsis txhob muaj npuas dej ntws los ntawm lub lauj kaub thaum lub sijhawm boiling, peb siv cov kev ua haujlwm yuam kev los txhim kho tus nqi evaporation kom ntseeg tau tias evaporation tus nqi yog 8-10% thiab txhim kho qhov kub kub.Kev quab yuam ncig nrog lub raj xa dej pab ua kom cov evaporation nce, thiab DMS qhov xwm txheej thiab cov ntsiab lus tsis pub dhau 30PPM, nws yuav txo cov cua sov thauj khoom thiab ua kom muaj kev ruaj ntseg ntawm wort chroma thiab tsis txhob wort Maillard cov tshuaj tiv thaiv.

2.Secondly, Tsawg zog noj hauv brewery

1.2.1 Condensate system ntawm kettle: Lub boiling boiling boiling system txais cov pa condensation rov qab system, nws yuav pab txhim kho cov dej rov qab thiab txuag cov dej thiab roj noj nyob rau hauv tag nrho cov brewery.Cov dej kub rov qab nyob ib ncig ntawm 80-85 ℃, thiab cov dej kub rov qab muaj peev xwm ntawm 300L rau txhua pawg;Qhov ntawd txhais tau tias nws yuav txuag tau cov roj 3m³ ib pawg ntawm cov dej kub ntawm 25-85 ℃.

1.2.2 Condersate dej los ntawm lub tsho: nws yuav pab tau zoo kom txuag tau dej thiab roj hauv lub tshuab hluav taws xob.Tsuas yog siv cov roj tsawg dua kom sov nws thiab ua kom sov thaum cov dej condensed rov qab mus rau lub tshuab hluav taws xob raws li cov dej condensed kub nyob ib ncig ntawm 80 ℃.

1.2.3 Wort cooler: Lub wort tshav kub exchanger cheeb tsam xam los ntawm cov txheej txheem brewing thiab ua tiav cov txheej txheem txias hauv 30 feeb, thiab cov dej kub kub ntawm 85 ℃ tom qab tshav kub pauv, kev sib pauv hluav taws xob ntau dua 95%.Yog li ntawd, peb yuav xyuas kom meej qhov siab tshaj plaws lub zog rov qab thiab txo cov nqi tsim khoom.

3.Support Customized kom tau raws li ntau homntawm npias

3.1Hops ntxiv cov cuab yeej ntawm lub hwj thiab muab cov hops qhuav tsis siv neeg.Raws li peb txhua tus paub North America brewer zoo li hoblos ntawm npias thiab muab ntau hops ntxiv rau saj ntawm hops.

3.2Tubular heat exchanger, Kom tso cai rau lub brewery kom txias lub wort ua ntej ntxiv whirlpool hop ntxiv.Muaj ib lub tubular hluav taws xob sab nraud kom txias cov wort tawm mus thiab rov qab mus rau hauv lub nkoj.

4.Ua tiav automatic brewhouse

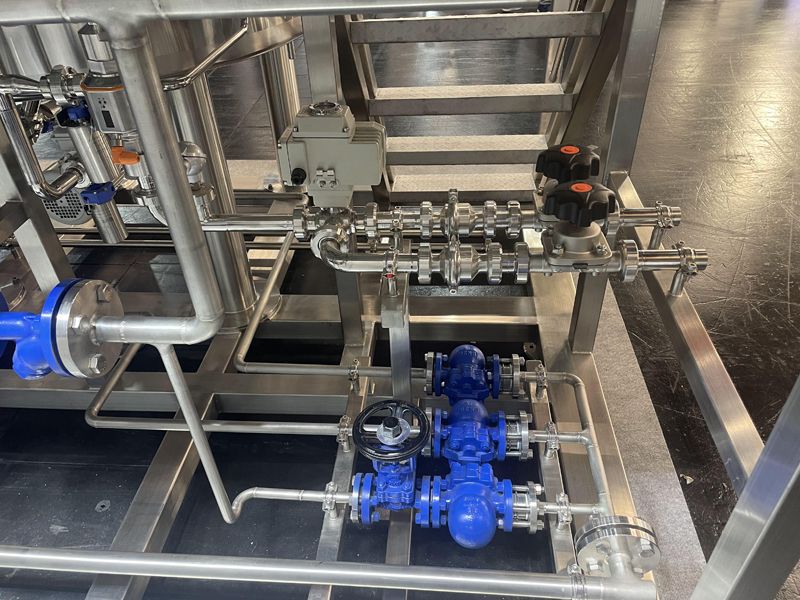

Kev lag luam automated brewing system yog ib qho kev siv thev naus laus zis tsim los ua kom yooj yim thiab txhim kho cov txheej txheem brewing ntawm kev lag luam.Lub tshuab brewing yuav muab kev ua haujlwm nrog lub pneumatic valve, tsis siv neeg tswj valve thiab qib hloov mus ua haujlwm tsis siv neeg ntawm cov dej nkag, pub mis, ntsuas kub, thiab lwm yam, yog li txhim kho kev ua haujlwm brewing thiab txuag kev ua haujlwm hauv brewery.

Lub automation ntawm cov haujlwm no tsis tsuas yog ua kom zoo dua ntawm npias tab sis kuj tso cai rau cov breweries ua haujlwm tau zoo dua, txo cov khoom siv, thiab ua kom muaj txiaj ntsig.

Rau mash kettle,

1.1 Lub ntsiab lus yog pre-masher, lub kaw lus nce yields, shortens mashing hauj lwm thiab ua rau ib tug qis iodine Performance index.The dynamic mixing system tiv thaiv cov tsub zuj zuj ntawm grist thiab txo cov kev xav tau ntawm lub zog rau kev sib tov.Yog li, cov husks raug tiv thaiv thiab lub sij hawm mashing yog luv luv.Tag nrho cov txheej txheem mashing tuaj yeem pom los ntawm cov iav pom zoo nkauj.Lub tsev yog kiag li CIP tshaj.

1.2 Agitator yog qhov ntws-optimized mixing system nrog ib tug tshwj xeeb ncig ntws thoob plaws hauv lub tiav ntim ntawm mash, txawm nyob rau hauv tsawg speeds.Cov qauv ntsuas no ua kom muaj qhov sib txawv ntawm qhov kub thiab txias hauv cov mash, nce yields thiab tiv thaiv husks.

Rau lauter tank,

1.1 Raker system yog tsis siv neeg nqa thiab siv cov nplej tsis siv neeg ib yam nkaus.Saj zawg zog grist load qhov siab thiab tsawg kawg lub sij hawm teem, peb lub cev tso cai rau ib tug saj zawg zog grist load qhov siab: Zoo meej lautering yog guaranteed tsis tau tsuas yog nrog heev grist loads, tab sis kuj nrog tsawg grist loads rau lub teeb beers.Qhov no ua rau lub kaw lus yog ib qho cuab yeej zoo tshaj plaws rau brewing ntawm craft npias.Feem ntau, peb lub kaw lus ua tiav lub sijhawm teeb tsa hauv qab 10-20 feeb rau kev siv cov nplej tshem tawm thiab yaug lub kaw lus, suav nrog sau cov lej cuav.Qhov no yog ua tau los ntawm kev txhim kho tsav tshuab ntawm kev siv cov nplej tshem tawm cov txheej txheem thiab los ntawm kev ua kom zoo, txuag dej ntws tawm ntawm qhov tsis tseeb hauv qab.

1.2 Sparaging system yog ze dua rau lub txaj txaj thiab tsis tawg uas rau cov pa oxygen tsawg dua thiab tsis cuam tshuam rau kev lim dej.

1.3 Kev sojntsuam ntev rau kev sib kis tau zoo, ob lub pob ntxuav ob qho tib si tu lub nkoj thiab iav manhole, tus ntaiv los pab koj mus xyuas sab hauv, Kev Tiv Thaiv net rau kev nyab xeeb brewer, pom teeb pom kev tawg-pov thawj, temp sensor thiab qib hloov txuas txuas rau Industrial txee kom ua tiav qhov tsis siv neeg version.

RauChaw nres tsheb dej, peb siv Pneumatic valve, tswj valve, temp testing, theem flow meter kom tsis siv neeg kho cov dej temp, ntws thiab dej ntim los ntawm kev tswj vaj huam sib luag.

Rauchav kab, tag nrho cov kev sib txuas yog flange los tiv thaiv cov pa tawm thiab xoob tom qab ua haujlwm ntev.Tsis tas li ntawd muaj lub valve rau ntawm no ntsia rau rov qab ntws ntawm condensate thiab Tiv thaiv dej rauj hauv cov kav dej.

Post lub sij hawm: Jan-23-2024