Tom qab 2 lub hlis ntau lawm, tam sim no peb ua tiav qhov kev tsim khoom ntawm 1000L brewery project thiab npaj xa tuaj.

Ntawm no cia peb pom cov ntsiab lus ntawm 1000L brewery system.

1.Malt milling tshuab nrog ob npaug rau cov menyuam.

2.1000L 3 lub nkoj brewhouse: Brewhouse seem yog qhov tseem ceeb tshaj plaws ntawm tag nrho cov brewery system., uas yog ncaj qha cuam tshuam nrog wort thiab npias zoo.

Lub modular tsim txuag lub sij hawm thiab nqi ntawm installation thiab commissioning.

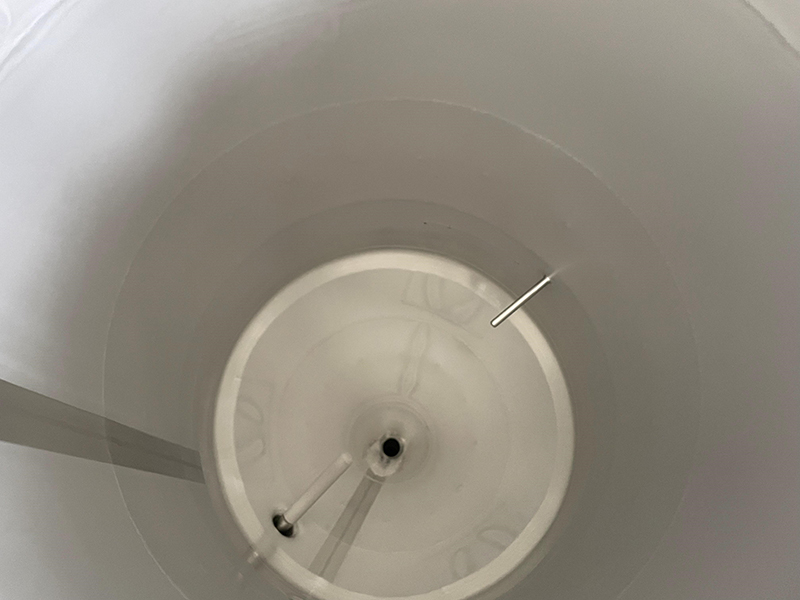

-Mash tun nrog chav rhuab, agitator nrog zaus tswj.

-Lauter tank nrog ob theem zaub los qhia qhov txawv ntawm ptessure, raker nrog zaus tswj thiab nqa nce thiab nqis.

-Whirlpool nrog chav rhuab, sab hauv tsev tso khoom.

-3 lub twj tso kua mis rau hloov wort nyob rau hauv txawv kettle.

-Platform: compact tsim nrog detachable Platform nrog kho ntsia hlau ceg.

-Flow meter nrog sib tov valve ntawm dej kub thiab kais dej.

-Hops lim txuas nrog rau qhov sib npaug, ib qho rau siv thiab ib qho rau seem.

-Brewhouse steam pipeline nrog flange kev twb kev txuas kom tsis txhob muaj cov pa xau.

| ||

|  |  |

|  |  |

|  |  |

3. Fermenter thiab unitank:

-6 teeb ntawm 10HL fermenter thiab 4 teeb ntawm 10HL Unitank.

-Cov fermenters thiab unitank fabricated los ntawm ASTE lub tuam txhab ua raws li qhov tsim nyog ntau yam khoom siv tes ua npias brewing thov thiab cov neeg thov tshwj xeeb.

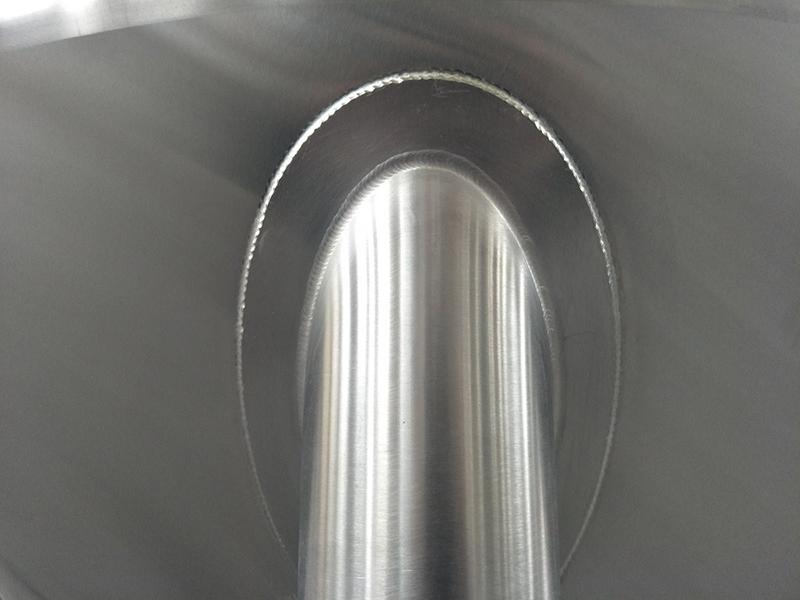

-Our cellae tso tsheb hlau luam yog tsim los ntawm stainless hlau 304, tag nrho cov tso tsheb hlau luam haum raws li PED ntawv pov thawj.Txhua qhov fittings siv cov khoom lag luam hauv Suav teb sab saum toj, tus qauv ruaj khov ntawm qhov zoo yog qhov tseem ceeb.

| Sab hauv ntawm fermenter | Racking caj npab | Siab regulator valve |

|  |  |

| Qauv valve | Spanding valve | Carbonation pob zeb |

|  |  |

| Vuam | Kev txhawb nqa ceg | Pob |

|  |  |

4.CIP Unit los ntawm ASTE

-50L 3 lub nkoj nrog hluav taws xob cua sov.

-Qhov no feem ntau yog siv los ntawm kev ntxuav ntawm micro brewery, tso tsheb hlau luam, twj tso kua mis, piping thiab li qub thiab lwm yam yog sib sau ua ke ntawm ib lub laub me me, uas ua rau kom yooj yim rau kev ua haujlwm thiab kev ua haujlwm.

|  |  |

5.Cooling system

-Txhua qhov system muaj chiller, glycol tank, HE, twj tso kua mis thiab lwm yam.

-Cov kua glycol zoo txuas nrog chiller thiab nyob rau hauv cov kev pab cuam digital rau kev tswj tsis siv neeg temp.

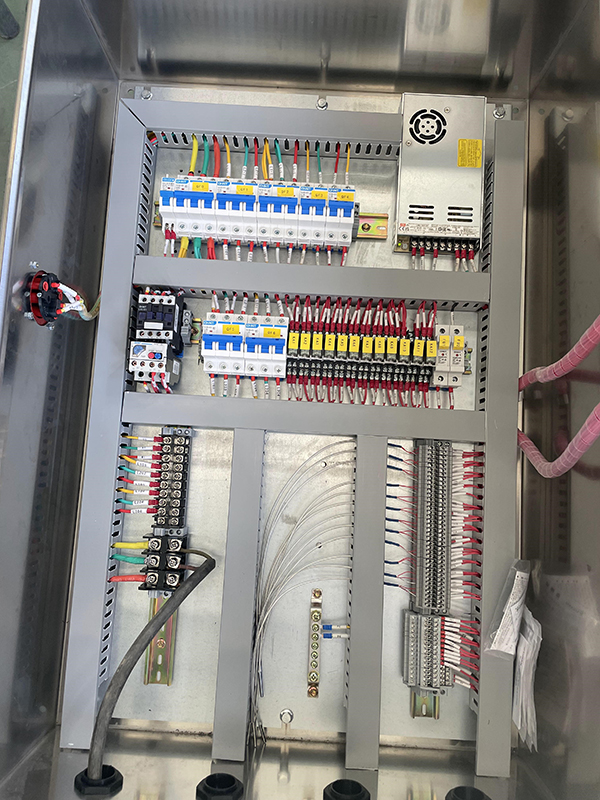

6.Control vaj huam sib luag

-PLC brewhouse tswj thiab Digital fermenters maub los.

-Txoj kev tswj hwm los ntawm ASTE ua raws li tus qauv tsim khoom noj & dej haus kev lag luam, ua ke nrog kev tsim kho tshiab raws li kev paub dhau los thiab kev txhim kho ntawm cov txheej txheem brewing.

-Lub temo teeb tsa thiab kev tswj ntawm mash, boiling, dej kub, fermenters, thiab lwm yam yog tiav los ntawm lub interface ntawm PLC kov screen los yog maub los, uas haum rau qhov sib txawv thov los ntawm ntau lawm.

| PLC brewhouse maub los | Controller npo |

|  |

| Fermenter maub los-digital | Sab hauv ntawm txee |

|  |

8.Lwm kev txhawb nqa

| Keg filler thiab washer | DE lim | Kev kho dej |

|  |  |

Cov saum toj no yog ua tiav ntawm 1000L npias khoom, Kuv vam tias koj tuaj yeem paub ntau ntxiv txog cov khoom siv brewery.

Cov cuab yeej no yuav raug xa tawm sai sai, thiab peb tab tom nrhiav rau pem hauv ntej kom pom cov neeg siv khoom sib dhos thiab tsim kom muaj txiaj ntsig ntau rau cov neeg siv khoom.

Cia peb saib nws.

Cheers!!

Post lub sij hawm: Aug-29-2022